Global supply chain networks have become increasingly complex for the food and beverage manufacturing sector, especially amidst the COVID pandemic. Supply chains have faced significant disruptions during this period, emphasizing the need for improved visibility. Achieving this means supply chain managers must incorporate the latest technology and data analytics tools to gain a comprehensive view of all operations and activities conducted throughout the process. It requires them to identify, monitor, and measure unknown business relationships between suppliers, vendors, and customers to reduce fluctuation in the flow of information and goods.

This can be done using data science and artificial intelligence. According to one report, over 50% of businesses use artificial intelligence in some kind of business operation. It’s especially useful for managing supply chain operations and allowing businesses in the food and beverage manufacturing industry to make more strategic decisions. They can use advanced supply chain mapping tools to improve supply chain visibility.

Why is supply chain mapping important, and how can AI and data science help with this? Let’s find out.

What Is Supply Chain Mapping?

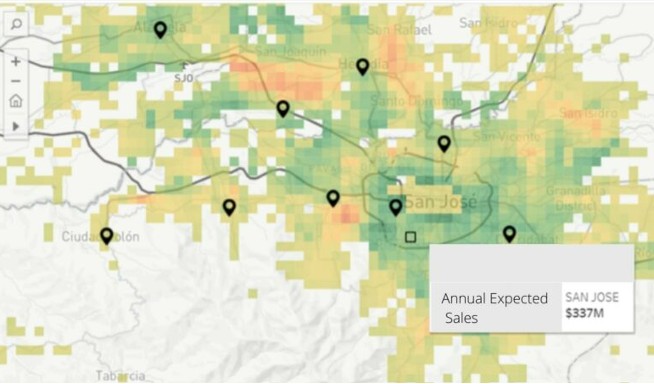

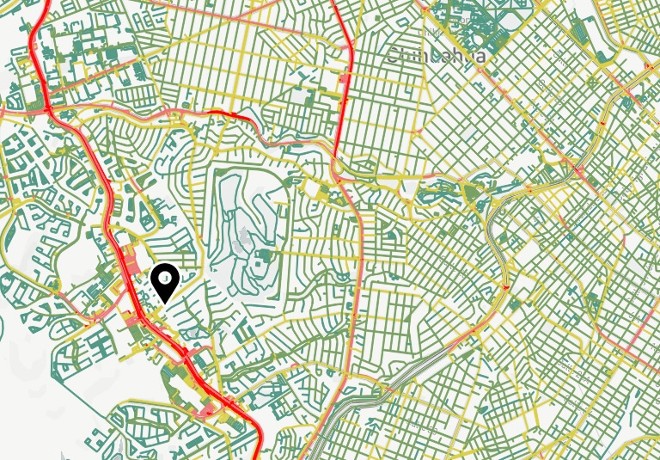

Supply chain mapping refers to the process of acquiring and visualizing data about suppliers, vendors, clients, and other stakeholders who are part of the supply chain network. This is done by using AI-based supply chain mapping tools to collect data regarding multiple different aspects of the supply chain process and network. The information gathered is then used to create a supply chain process map and gain insights into the flow of goods.

Supply chain mapping helps food and beverage manufacturing businesses visualize different informational elements of their supply chain networks. For instance, they can use the supply chain maps to identify specific areas where business activity is high, track inventory, and oversee various other daily activities involved in the supply chain management process. This enables them to analyze data better and develop more effective strategies.

AI-based supply chain mapping tools also allow business owners to better understand the different tiers in their supply chain networks. They can use this analysis to streamline procedures, make evidence-based claims, build credibility, and implement transparency, boosting supply chain visibility along the way.

They Can Improve Demand Forecasting

One of the biggest advantages of using artificial intelligence in the supply chain is that it allows businesses to conduct accurate demand forecasting. This is essential for supply chain management as it allows them to establish optimal inventory levels. Doing so enables them to improve stock ability while lowering holding costs.

Managing inventory is a challenging task in the food & beverage manufacturing sector. An incorrect estimate of future demands can result in businesses stocking up too much or too little of certain products, leading to significant monetary losses.

Using AI-based mapping tools can prevent this outcome. AI systems use predictive analytics to study previous market trends, signals, and performance indicators. They analyze the data at hand to forecast demands accurately and help warehouse managers determine how much of each product they need to stock. This prevents inventory surplus and deficit.

Additionally, AI mapping tools can help identify patterns and detect emerging threats for effective forecasting. This helps supply chain managers take necessary action before there are any disruptions in the supply chain, staying ahead of their competitors.

They Facilitate Informed Supplier Selection

Finding the right product supplier is essential for food & beverage manufacturers. They must adhere to industry standards and FDA regulations, evade ethical issues and scandals, and consistently produce high-quality edible items to stay ahead in the industry. Partnering with the wrong vendor or supplier can harm their reputation and slow down operations, dampening productivity.

AI supply chain mapping tools help manufacturers better understand their suppliers. They can assess their potential partners’ business history and performance, identifying potential risks. This allows them to make more informed decisions when selecting suppliers and partnering with a particular vendor after weighing the pros and cons. They can also mitigate financial and PR risks, ensuring their customers aren’t affected by who they work with.

They Enable Optimized Route Planning

Supply chains in the food & beverage manufacturing sector are under pressure to deliver products as per preset deadlines. Since most products are perishable or have fast-approaching expiration dates, they must be shipped and delivered on time in the most effective way possible.

Artificial intelligence tools can help with this as well. Supply chain mapping tools help manufacturers analyze multiple traffic patterns and weather conditions to determine the best course of action. This allows them to plan routes more effectively, reduce transportation costs, and prevent delays and product wastage.

Supply Chain Mapping Tools for Food & Beverage Manufacturers

PREDIK Data-Driven provides artificial intelligence-supported supply chain mapping tools and software to food & beverage manufacturers in the United States. They offer predictive analytics and big data analytics solutionsto help businesses effectively study their supply chains and implement best practices.

Comments are closed.