If you work in engineering or design, you know that CFD software is a powerful tool that helps predict fluid flow, heat transfer, and other physical phenomena in your models. Modern CFD tools make it easier than ever to test and optimize designs without building expensive prototypes. The right setup ensures accurate results, reduces computation time, and helps engineers make smarter decisions during the design process. Whether you are modeling air, water, or other fluids, following best practices in geometry preparation, meshing, and boundary definition can significantly improve your simulation outcomes and this is where CFD Software is essential.

Step 1: Prepare Clean Geometry

The first step in any CFD simulation is to ensure your CAD geometry is clean and ready. Clean geometry is enclosed, free of gaps or cracks, and has smooth surfaces. Every part should be clearly defined, with no overlapping faces or small details that do not impact the physics but could slow down the simulation. Simplifying geometry without losing critical features is key to creating a solid base for your CFD analysis.

Once your geometry is ready, create a computational domain around it, often using a geometric box. This domain defines the area where the fluid will flow and where the solver will calculate physical quantities. Refining this domain in areas of interest helps improve accuracy without excessively increasing computation time.

Step 2: Apply Proper Mesh Refinement

Mesh quality is one of the most important factors in CFD accuracy. A mesh divides your fluid domain into small cells where the solver computes the equations of fluid motion. Key tips for good meshing include:

- Boundary Layer Refinement: This ensures that areas near walls or surfaces where fluid behavior changes rapidly are modeled accurately. Refining the boundary layer improves turbulence predictions and heat transfer results.

- Balance Accuracy and Computation Time: Finer meshes improve results but require more computing power. Perform a mesh convergence study to find the right balance between precision and simulation speed.

- Use Automated Tools Wisely: Many CFD programs offer automatic meshing, but the first iteration may not be perfect. Adjust settings and use mesh converters or filters to enhance the mesh quality where needed.

Good mesh setup prevents common issues such as solver instability, unrealistic results, or excessively long computation times.

Step 3: Set Correct Boundary Conditions

Boundary conditions define how fluids enter, exit, and interact with surfaces in your simulation. Correct boundary conditions are essential for realistic results. Common steps include:

- Defining inlet and outlet flow properties

- Specifying wall conditions, including no-slip or heat transfer surfaces

- Applying symmetry planes or periodic boundaries when appropriate

It’s also important to assign material properties correctly, such as density, viscosity, and thermal conductivity. These details directly affect how the solver models the physics of your problem.

Step 4: Run the Solver and Monitor Progress

Once your mesh and boundary conditions are ready, you can run the simulation. Many CFD programs, like scFLOW or scSTREAM, allow adaptive meshing, which adjusts the mesh during the simulation to improve accuracy in regions with high gradients. Monitoring key parameters during the run ensures the solver converges correctly and avoids errors.

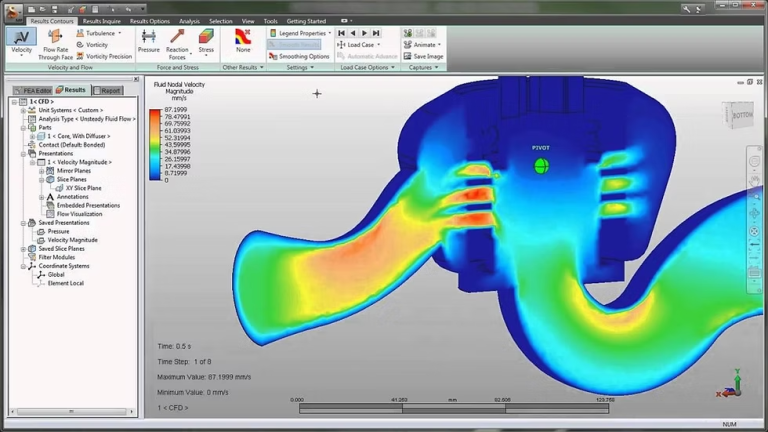

Step 5: Post-Processing and Analysis

After the simulation completes, post-processing lets you visualize and interpret results. This stage is crucial for making design decisions. Look at velocity fields, pressure distributions, temperature profiles, or any other relevant outputs. Post-processing helps identify areas where design changes can improve performance, reduce energy consumption, or enhance safety.

Tips for Efficient CFD Workflow

- Start Simple: Begin with a coarse mesh and simple models to check setup and reduce errors. Refine later for final results.

- Automate Repetitive Tasks: Use scripts or built-in software tools to handle repetitive boundary assignments or mesh adjustments.

- Document Settings: Keeping records of mesh sizes, boundary conditions, and solver parameters ensures consistency for future simulations.

- Validate with Real Data: Whenever possible, compare CFD results with experiments or field measurements to verify accuracy.

Final Thoughts

Setting up a successful CFD simulation requires attention to detail, from clean geometry to mesh refinement and boundary conditions. Using CFD software effectively can save time, reduce costs, and improve design quality. Modern tools like scFLOW and scSTREAM simplify the process by offering adaptive meshing, solver automation, and advanced post-processing. By following these tips, engineers and designers can achieve more reliable simulations, explore innovative designs, and make informed decisions faster.

Comments are closed.