If you’re in the market for a hydraulic cylinder, you may have come across the terms “single-acting” and “double-acting.” But what exactly do these terms mean? Let’s start with single-acting hydraulic cylinders. In other words, they only work in one direction.

So, if you need a cylinder that can both push and pull, you’ll want to look into double-acting cylinders instead. Keep reading to learn more about the differences between these two types of hydraulic cylinders!

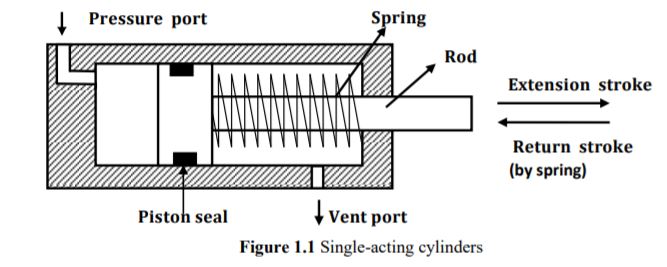

Single acting hydraulic cylinders are a simple and straightforward solution for applications that require force in one direction. It uses hydraulic fluid to push the piston and load with pressure from a pump through an oil port, causing the rod to extend.

The retract function of the single-acting cylinder requires a spring or other external component to retract it back to its original position once the load has been lifted. While this design avoids some of the disadvantages of double-acting cylinders such as requiring less power and components like guides and lights, it also forces all of the pounds generated by the load onto the tool being used.

Overall, when considering which type of cylinder to use, both models have their advantages and disadvantages depending on the application. If simplicity is key, then the single-acting cylinder may be your best bet; however, if you need more versatility and control over the force being applied, then a double-acting cylinder might be necessary.

So, next time you enter the market for a hydraulic cylinder, make sure you understand the differences between single-acting and double-acting cylinders before making your purchase.

Which is Better: A Single or Double-Acting Cylinder?

Both Cylinders use a piston and port to extend and retract, but the main difference lies in their design. Single-acting cylinders only function in one direction and require an external force, such as a spring or weight, to return to their original position. On the other hand, double-acting cylinders can operate in both directions and have built-in control mechanisms that allow for more advanced movement and pressure control.

While single-acting cylinders may seem more simplistic and straightforward, they also come with certain disadvantages. For example, they can only push in one direction and may require additional components to avoid excessive forces on the opposite end. Ultimately, the choice between single-acting and double-acting hydraulic cylinders depends on the specific needs of the application and should be guided by expert advice from sales representatives or industry professionals who are well-versed in the different types and models available on the market today.

Comments are closed.